MA-Φ114 High Frequency Welded Pipe Mill

Description

Videos

Specification:

Finished product: Round Tubes, Square and Rectangular Hollow Sections

Round Tube Outside Diameter: Min 22, Max 114mm

Square Hollow Section: Min25x 25, Max 90 x 90 mm

Rectangular Hollow Section: Min 25 x40, Max 80x 120 mm

Tube Thickness: Min 1.2, Max 4.5 mm

Forming Line Speed: Max 60m/min (Square and Rectangular Hollow Shapes are produced at lower speeds depending on side to wall thickness ratio)

Tube Cut Length: Min 4 Max 12 meter

Length Accuracy: ± 3mm

Main Drive Motor: DC 90kW×2

Line Composition:

Double Mandrel Uncoiler.

Shear and TIG Welder.

Horizontal Strip Accumulator.

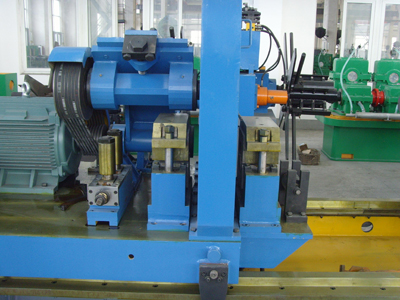

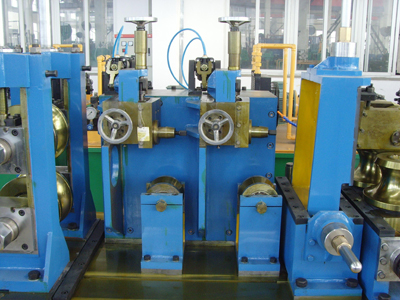

Forming, Welding, Cooling and Sizing Section.

Computer Flying Saw Cut-Off.

Straightener:

End Milling and Chamfering Machine

Baling Press

Driven Roller Run Out Table, Inspection table & Collectors.

Solid State H.F. Induction Welder: 300 kW, Solid State (400kW, Vaccum Tube Type) Type

Rolls: Rolls are manufactured out of AISI D3 D2 E52100

Electrical Panels

Tags: